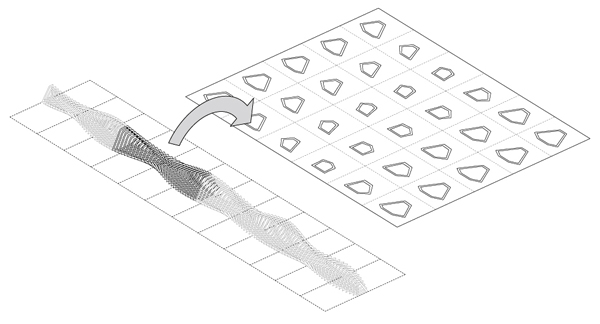

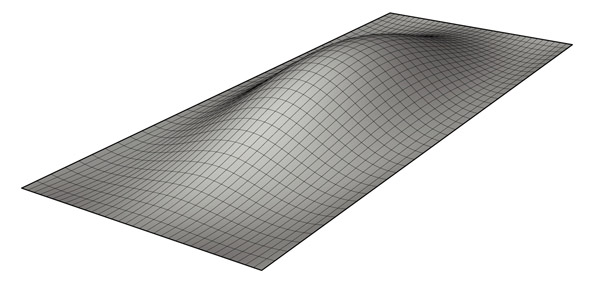

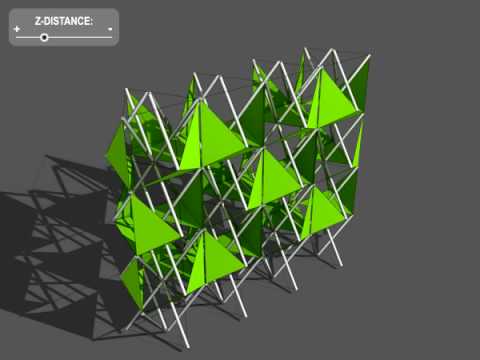

The FLUX exhibition opened last night at the California College of Arts and we had an incredible turnout. The exhibition explores contemporary architecture and design through its relationship with changes in design technologies such as parametric modeling, digital fabrication, and scripting. Over 40 projects are featured in the exhibition through drawings, photographs, and specially made models that explore the techniques and processes presented in the projects. Eight topics dealing with the geometric and performative aspects of the projects are explored: Stacked Aggregates, Modular Assemblages, Pixelated Fields, Cellular Clusters, Serial Iterations, Woven Meshes, Material Systems,Emergent Environments. I was brought in as a parametric modeling and complex geometry consultant to write a Grasshopper definition that would generate the form, ribs, plexi-glass panels, and all of the connection details. These would in turn be flattened in Rhino so they could be sent directly to the CNC mill. Final fabrication started just 2 weeks before the opening and because all of the details had been controlled in the parametric model, each of the 4 modules could be constructed in just two and half hours.

Director of Architecture, CCA: Ila Berman

Project Design and Fabrication: Kory Bieg, Andre Caradec, Andrew Kudless

Parametric Design Consultant: Andy Payne

Sponsors: K Bieg Design, Studio Under Manufacture, Solid Thinking

Photos courtesy of Kory Bieg